Modelling, Simulating & Optimizing Formula SAE Chassis using SolidWorks & ANSYS

Project Summary

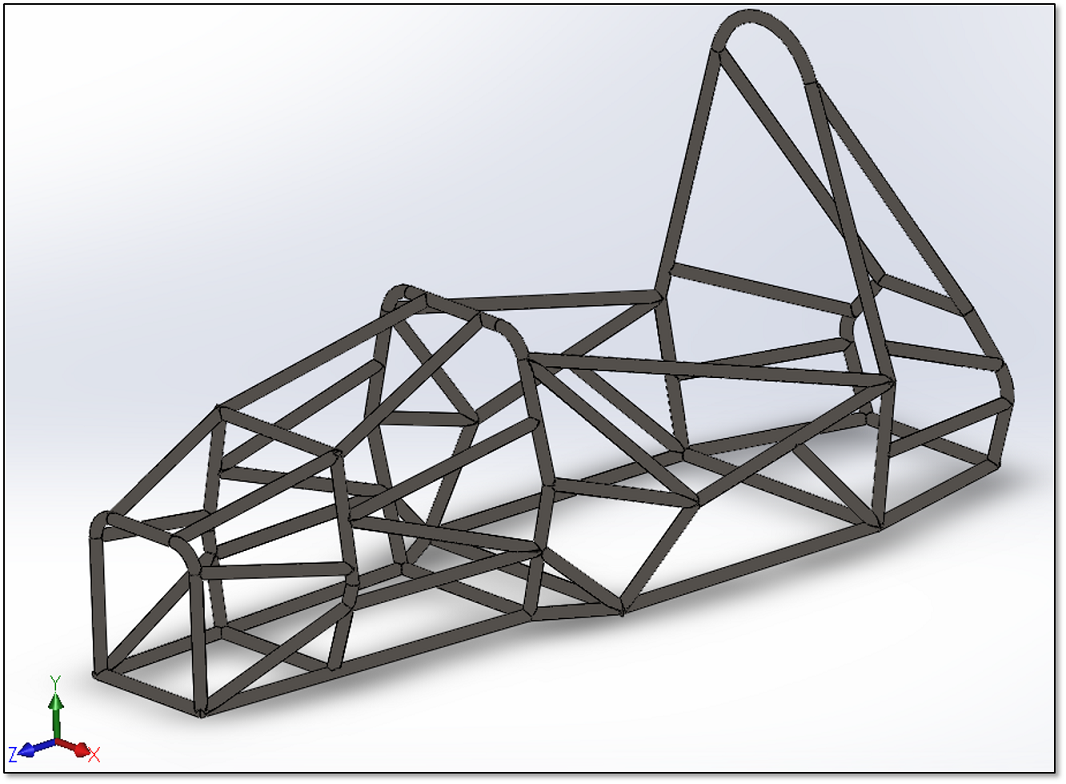

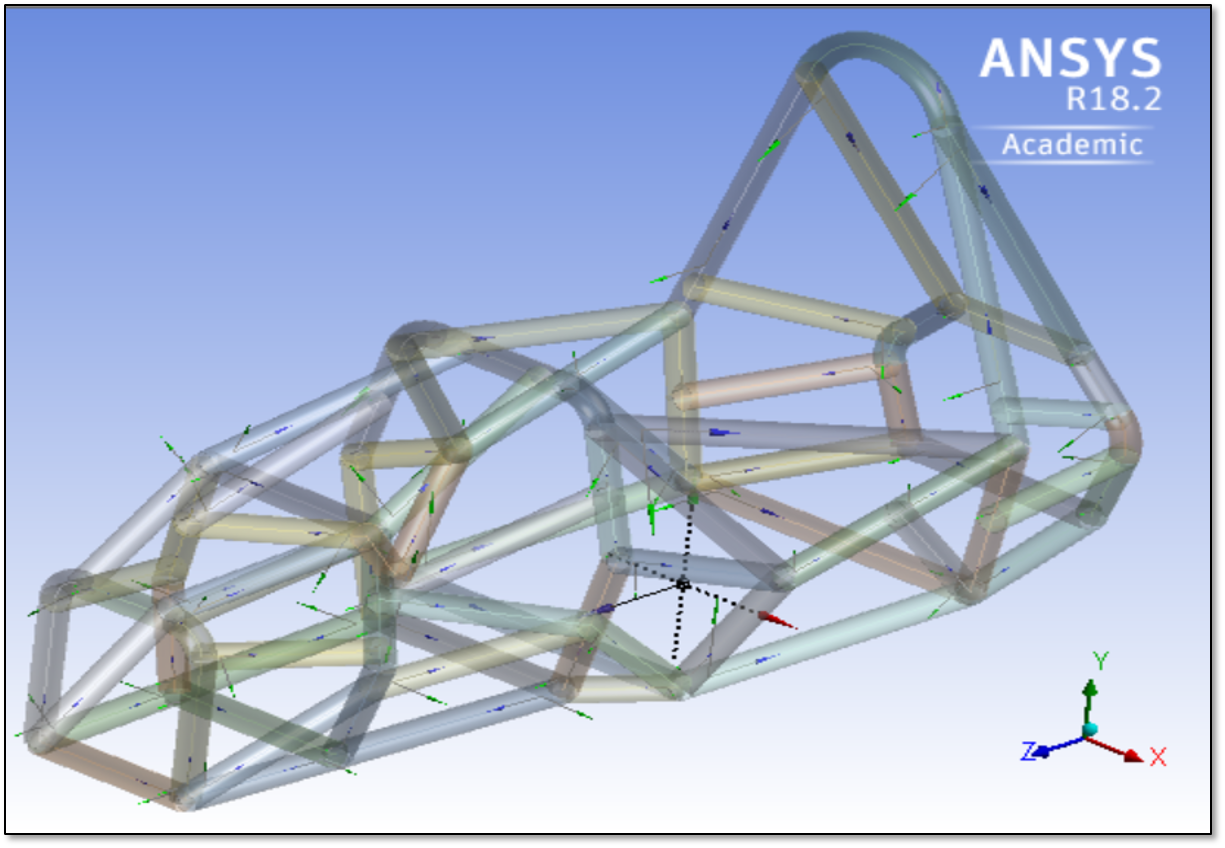

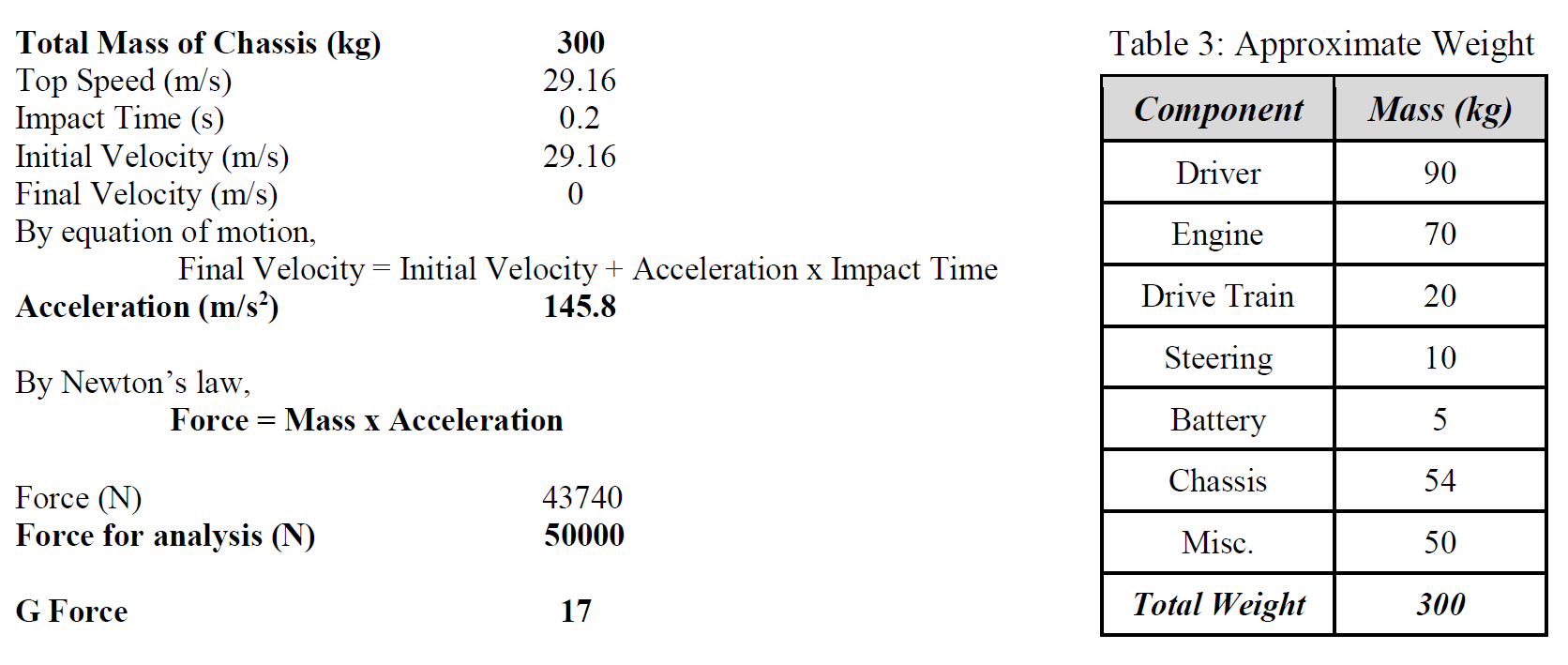

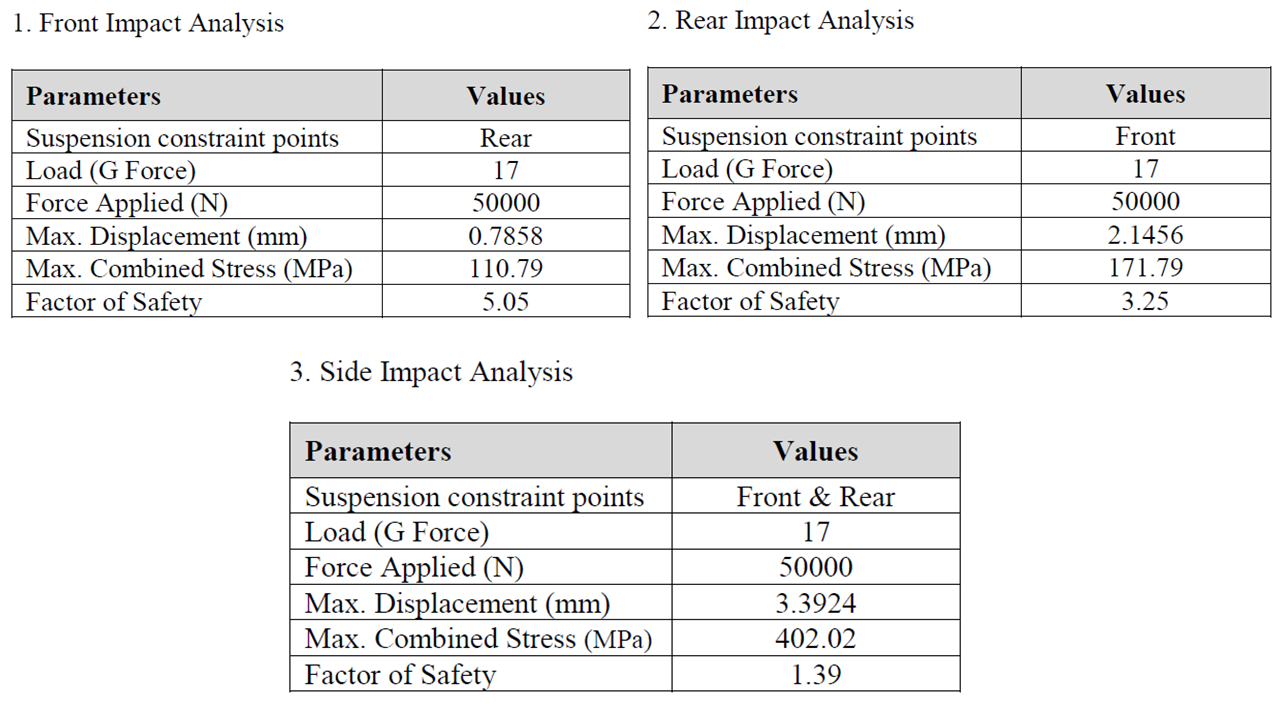

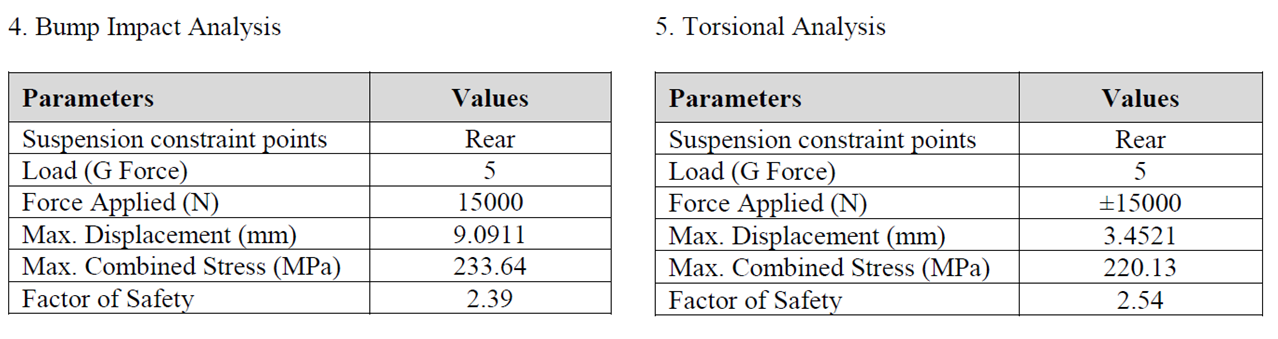

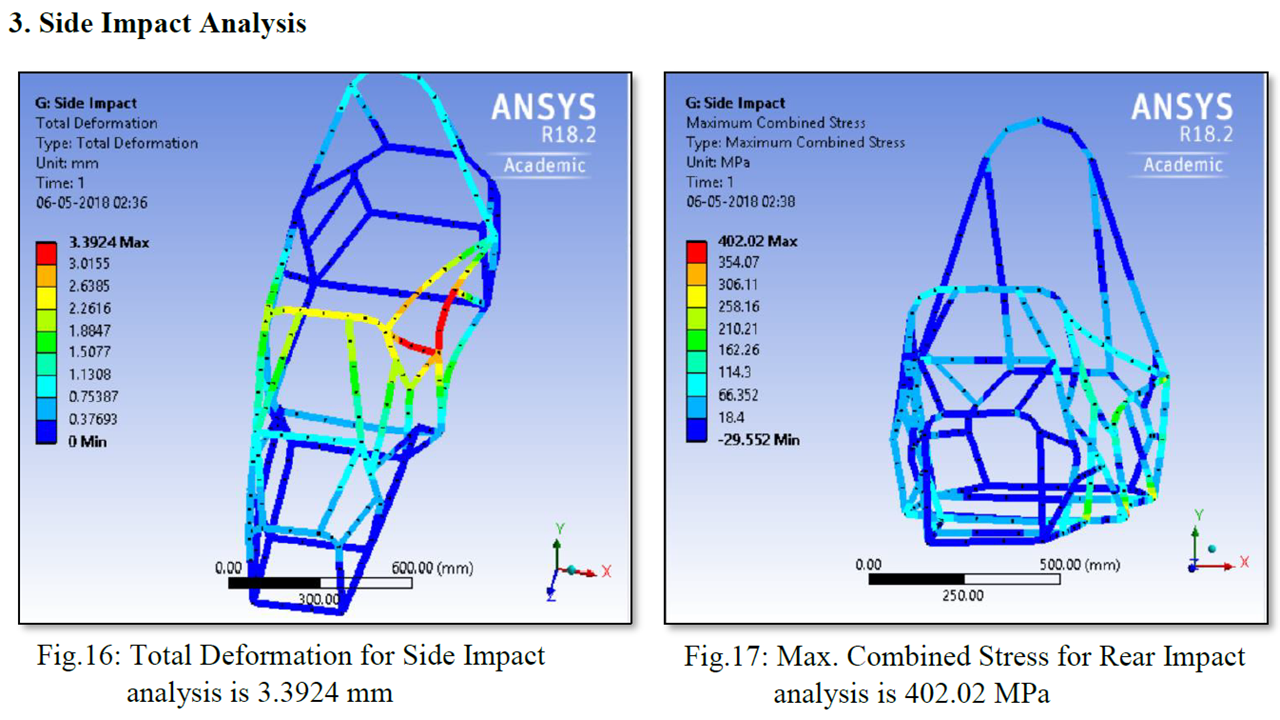

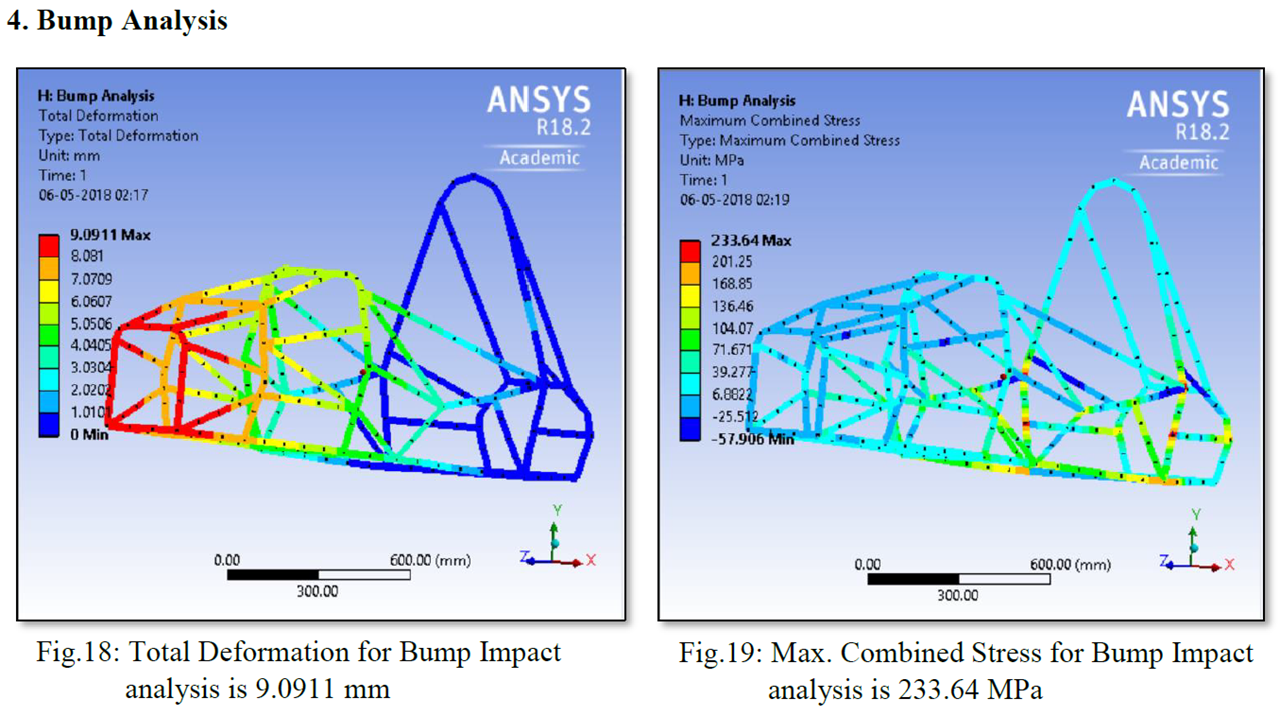

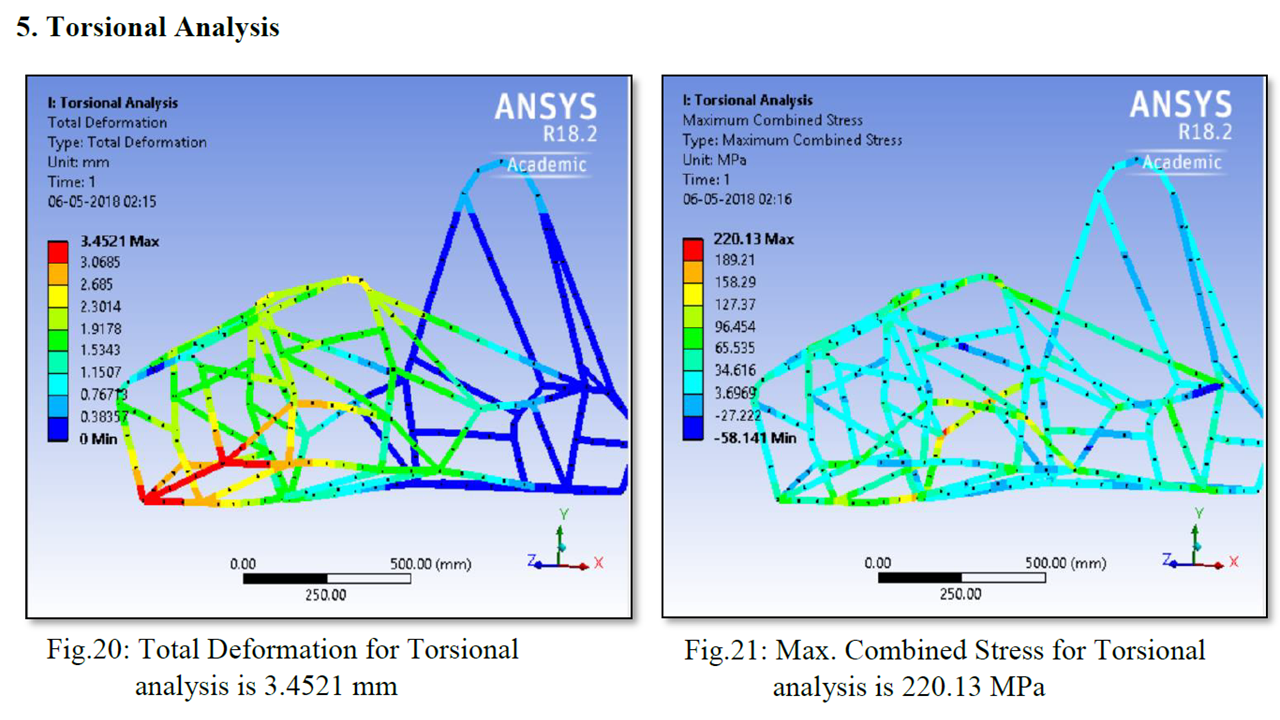

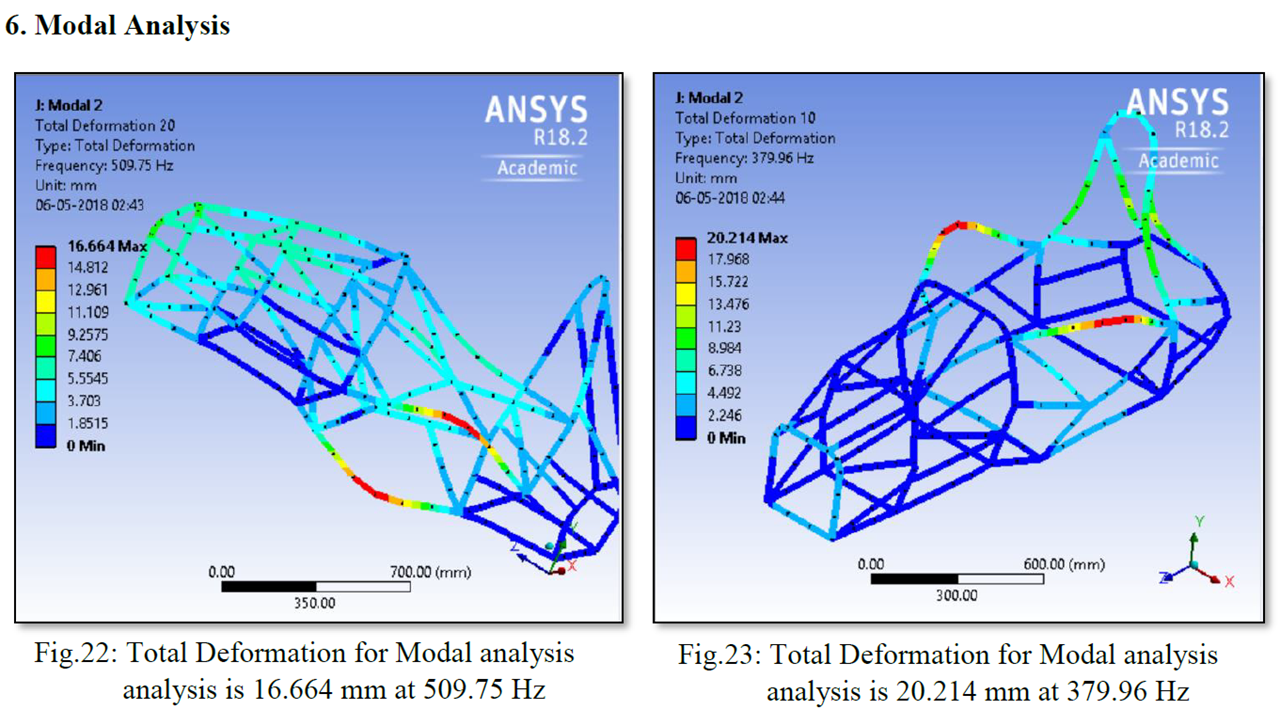

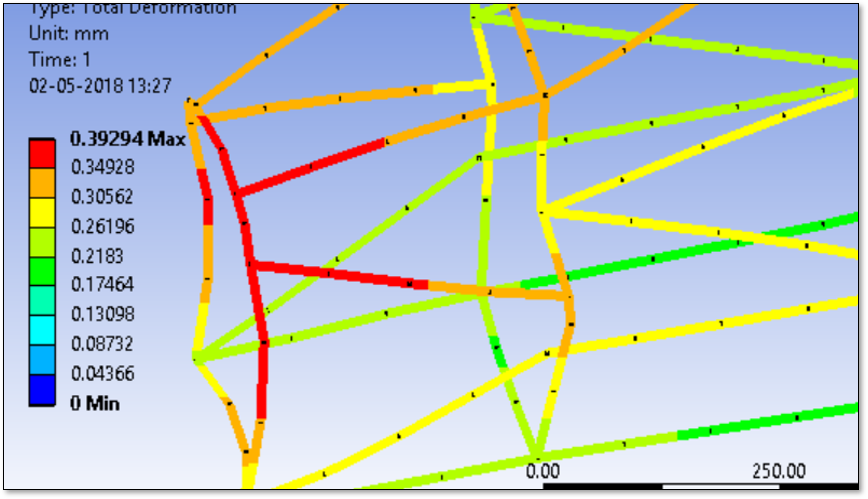

• Modelled a torsionally rigid FSAE chassis to ensure safety, ride, handling & stability using Finite Element Analysis, saved computation time, and verified it for stress, strain, deformation, torsional analysis.

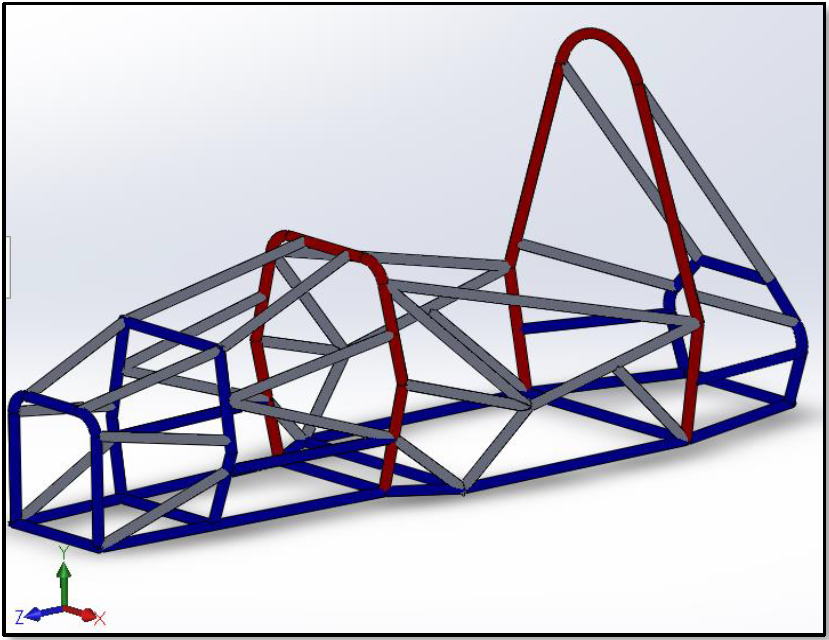

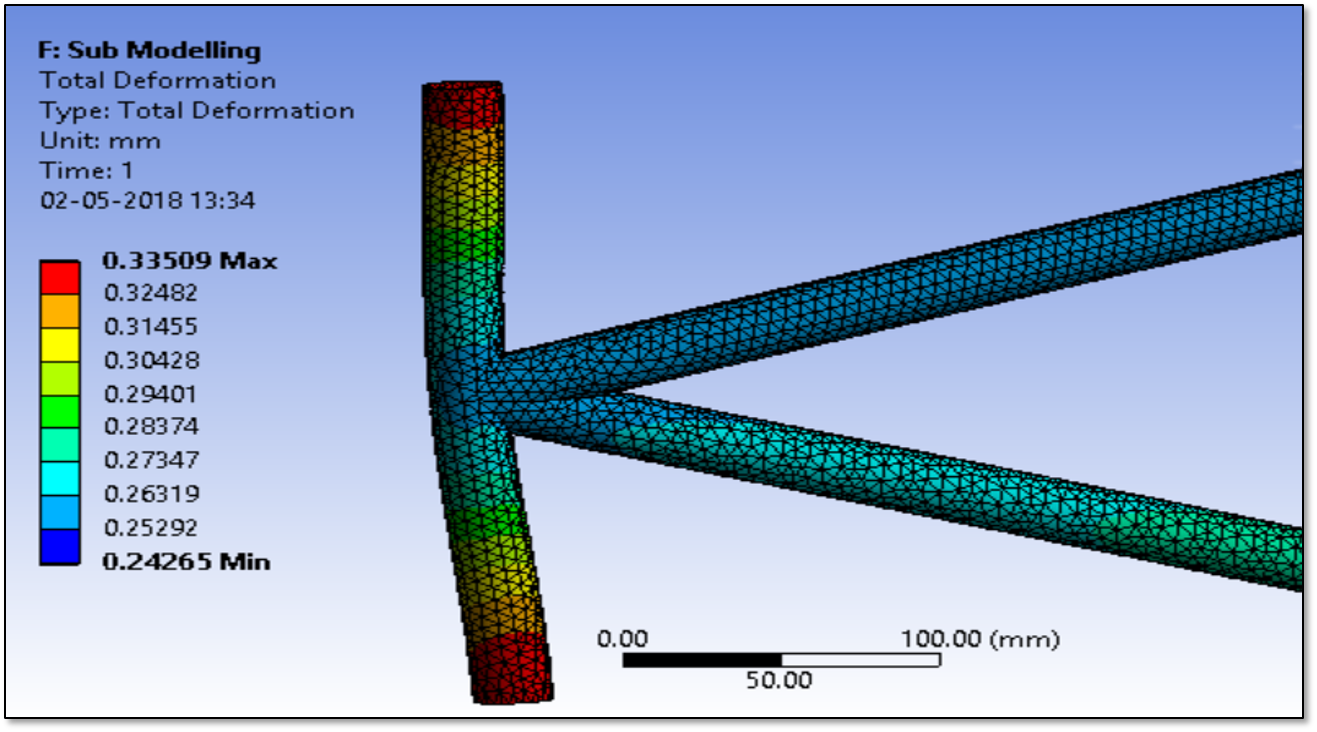

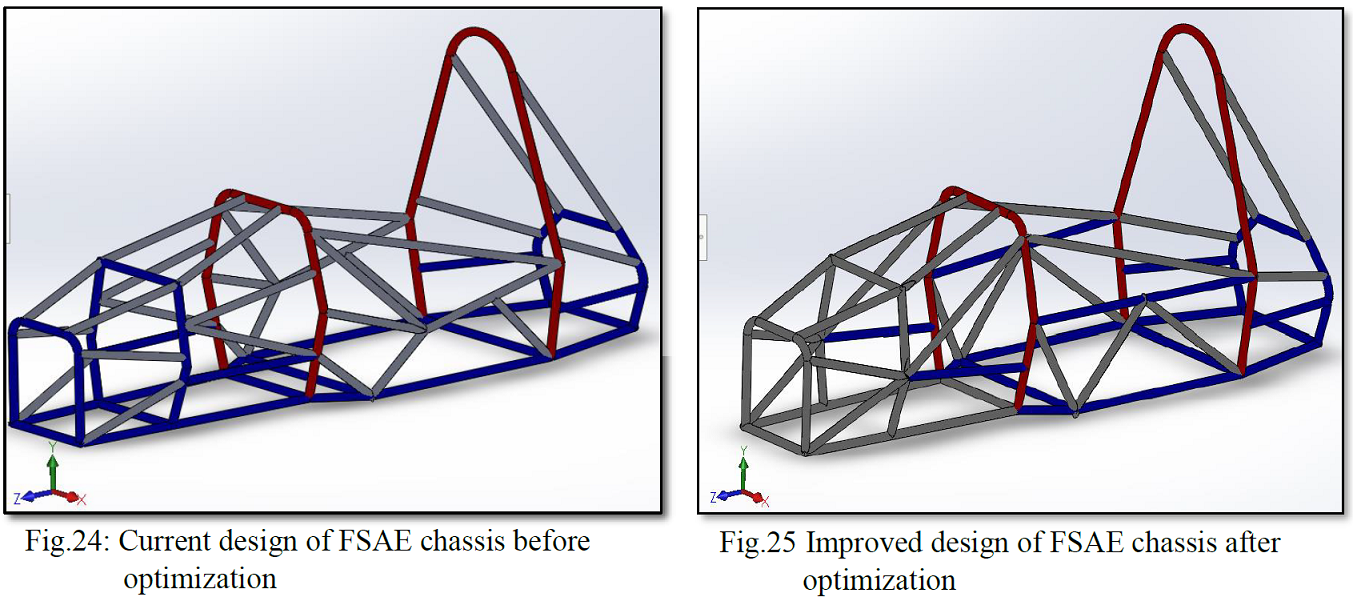

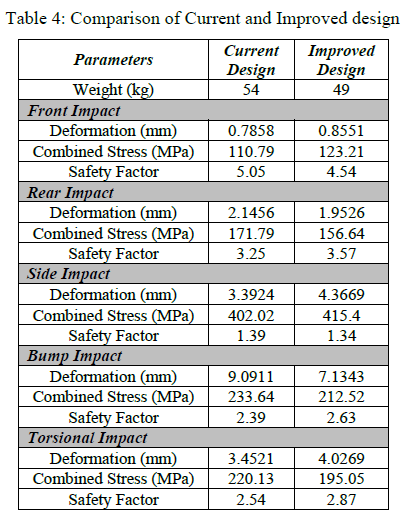

• Redesigned and optimized the existing chassis by 20% in weight, reduced material and cost by using Submodelling techniques for critical parts without compromising the safety requirements

• Redesigned and optimized the existing chassis by 20% in weight, reduced material and cost by using Submodelling techniques for critical parts without compromising the safety requirements

Software & Skills

Highlights

- Designed an FSAE chassis using SolidWorks following the guidelines given in the rulebook.

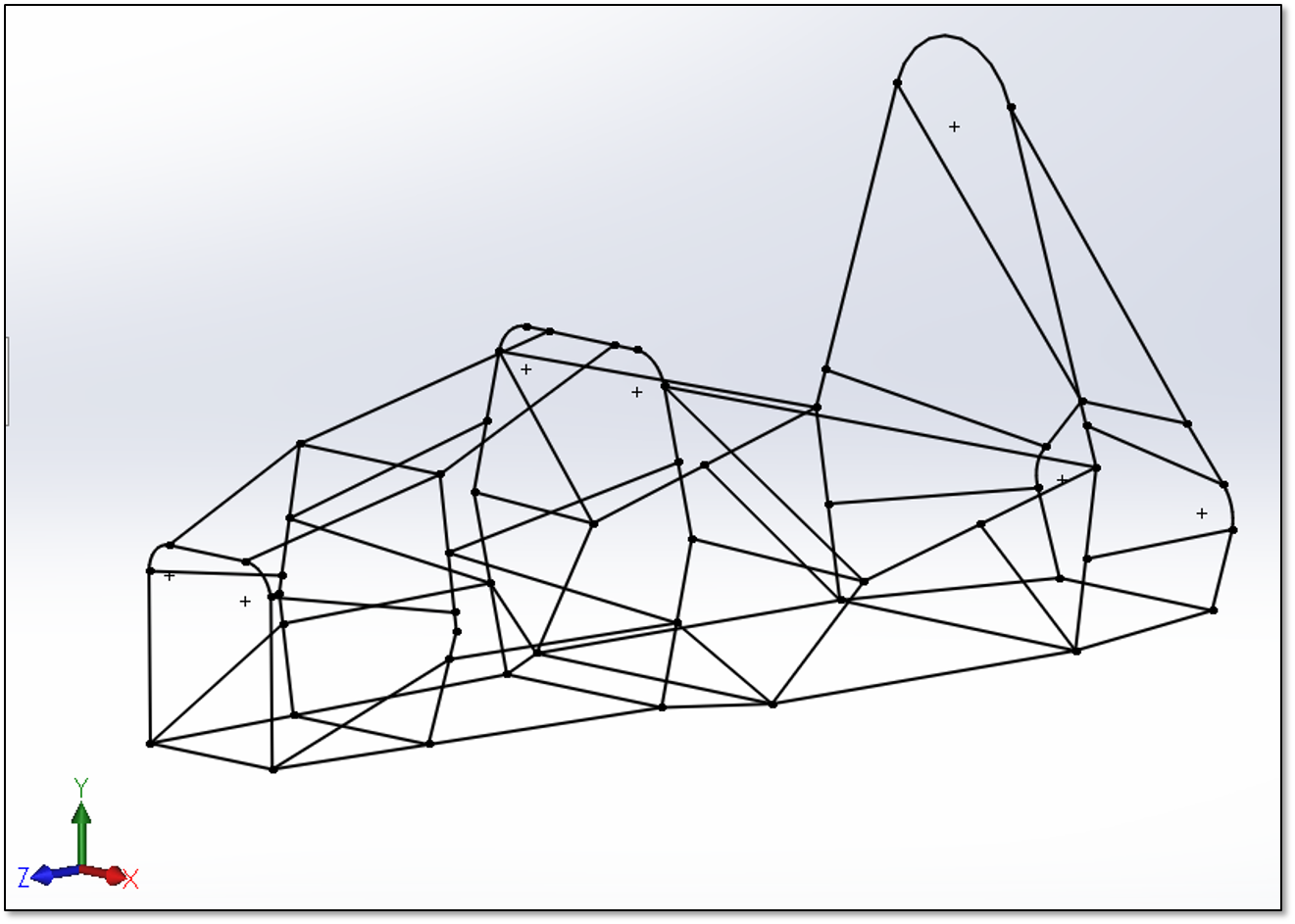

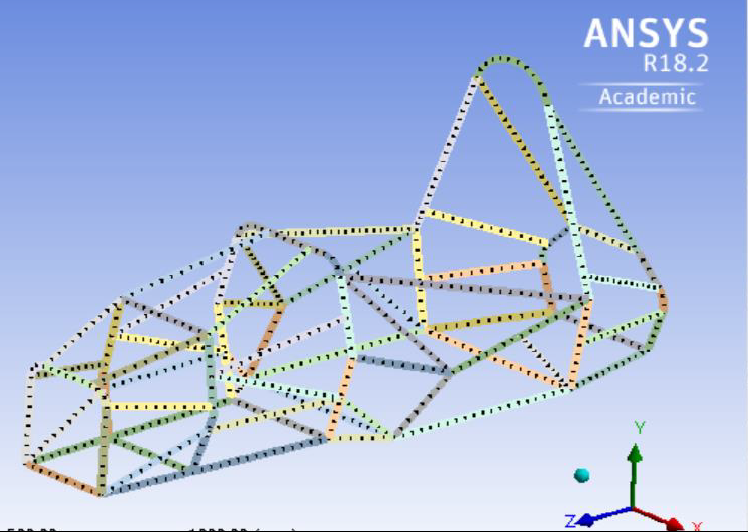

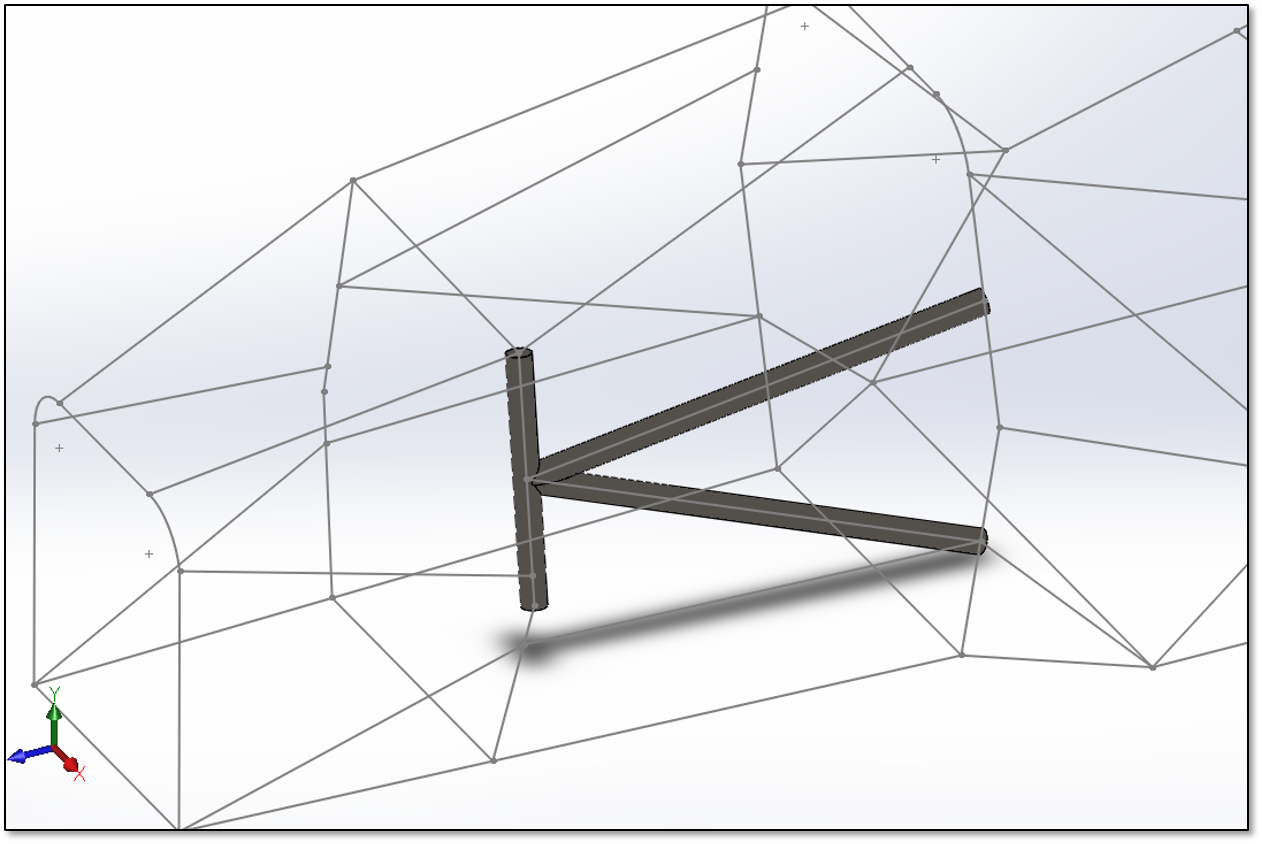

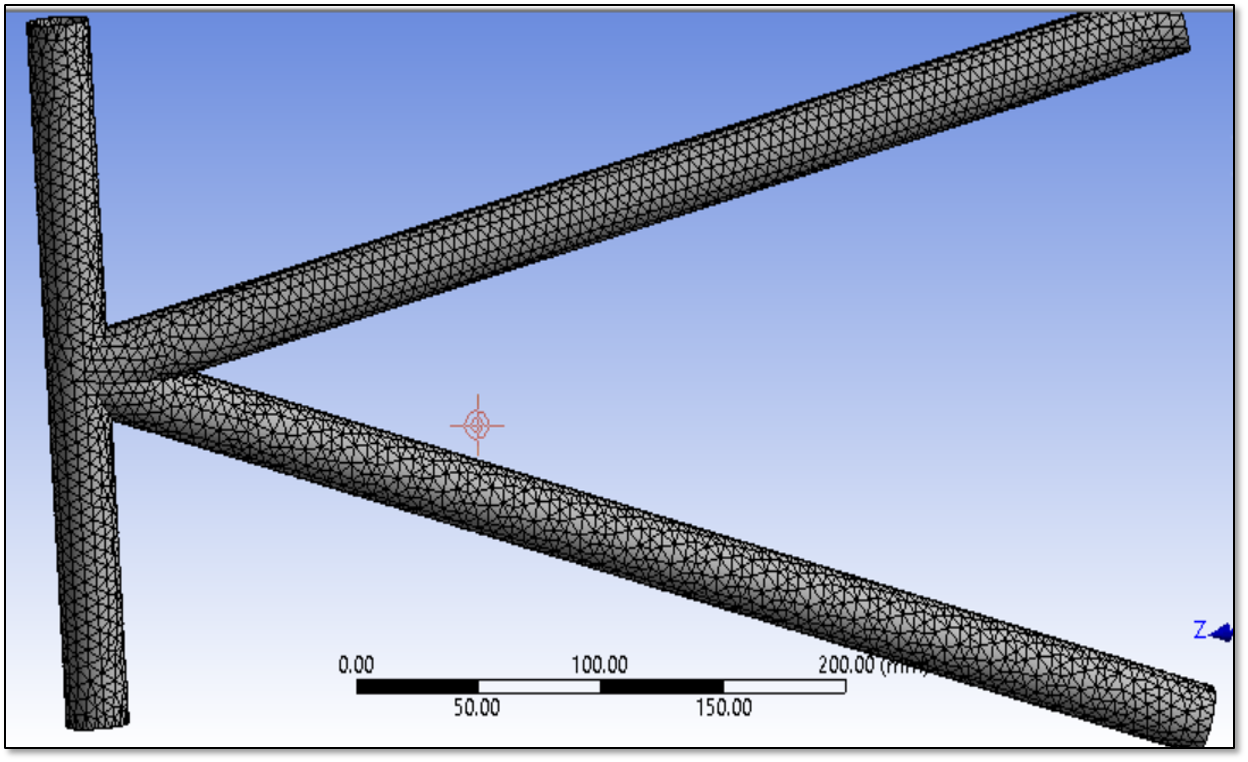

- Conducted detailed design methodology analysis of Beam element (1-D line), Shell element (2-D plane) and Solid element (3-D solid) based on the accuracy and computation speed.

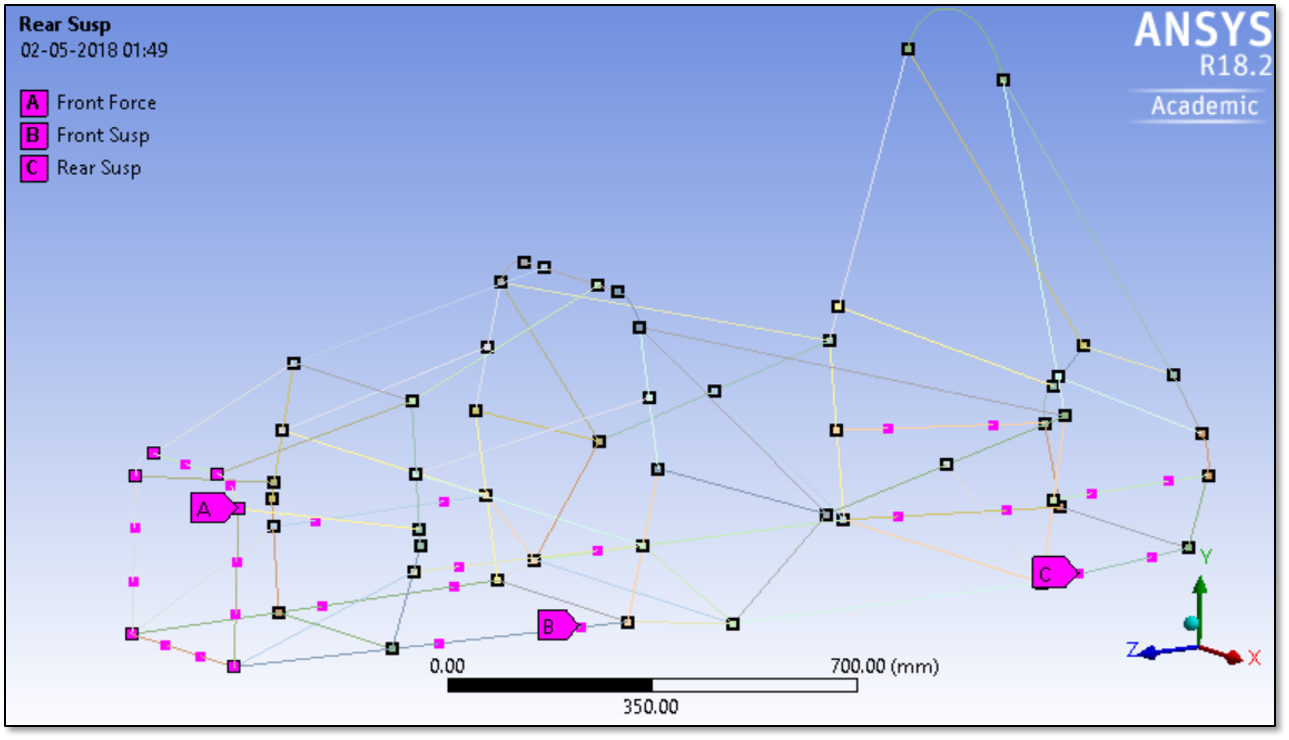

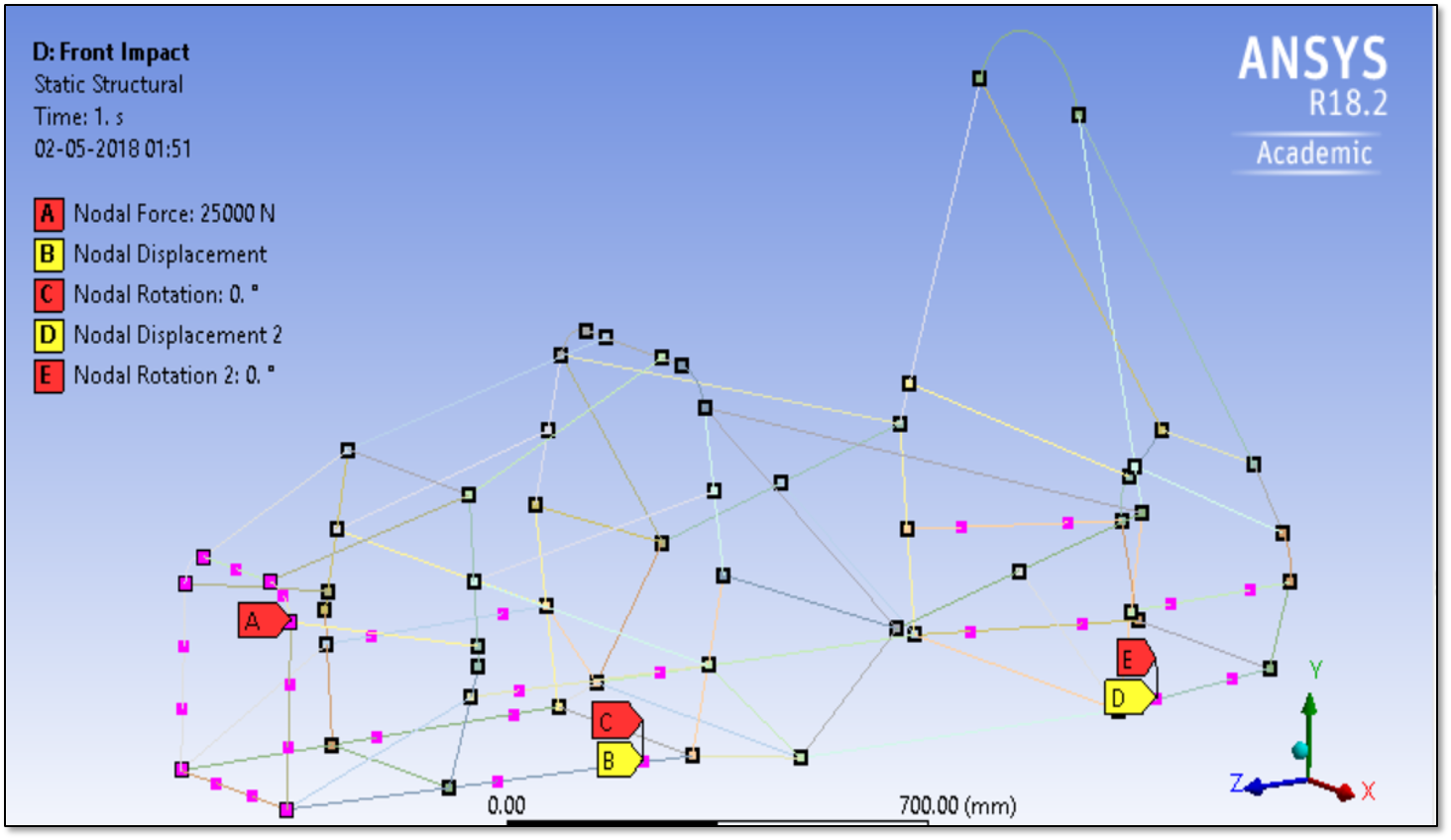

- Created global and local model of the chassis to scrutinize critical components and get super accurate results.

- Analyzed the chassis for twisting, vibrations, shock, buckling and other variety of stresses due to loads, forces, weight transfer etc.

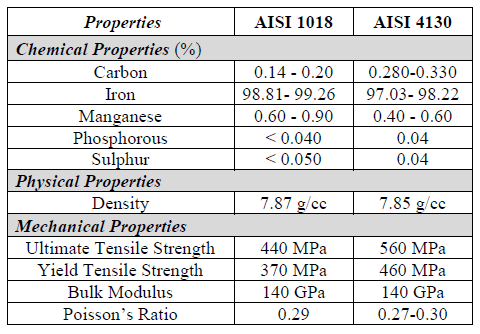

- Compared different materials like Chromoly steel 4130 & 1018 based on strength to weight ratio, density, machinability, chip formation and corrosion resistance.