PLC Programming for Automating Industrial Processes using AB Rockwell Automation & Siemens

Project Summary

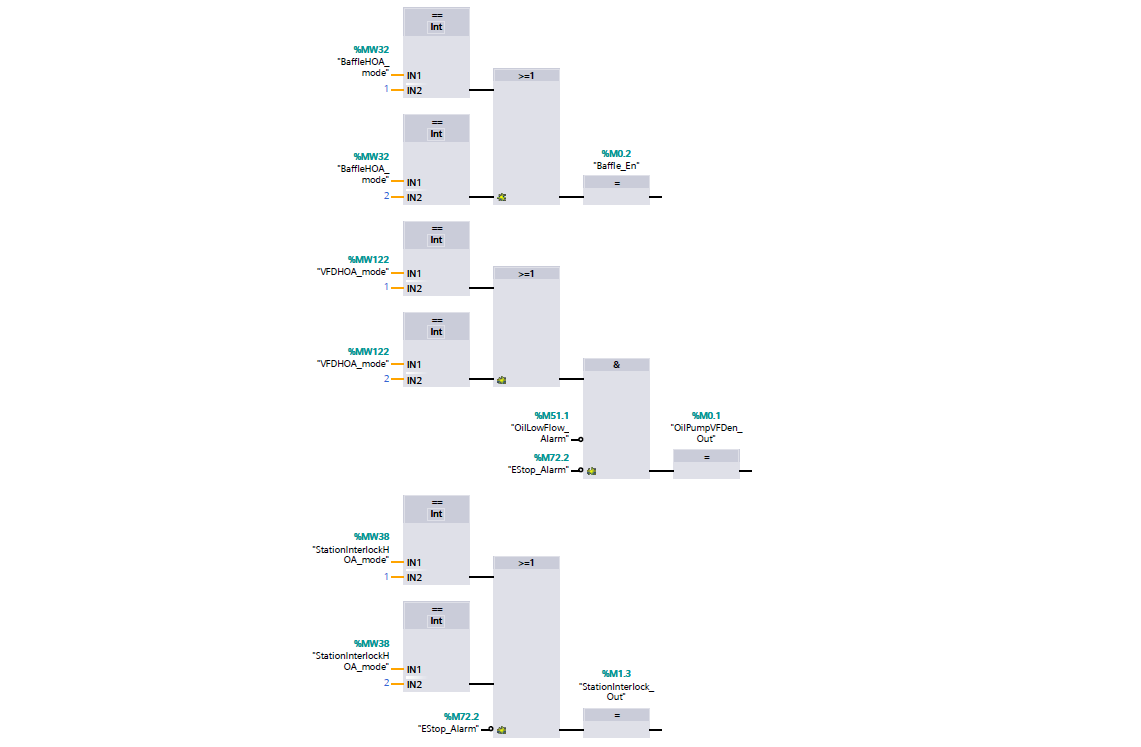

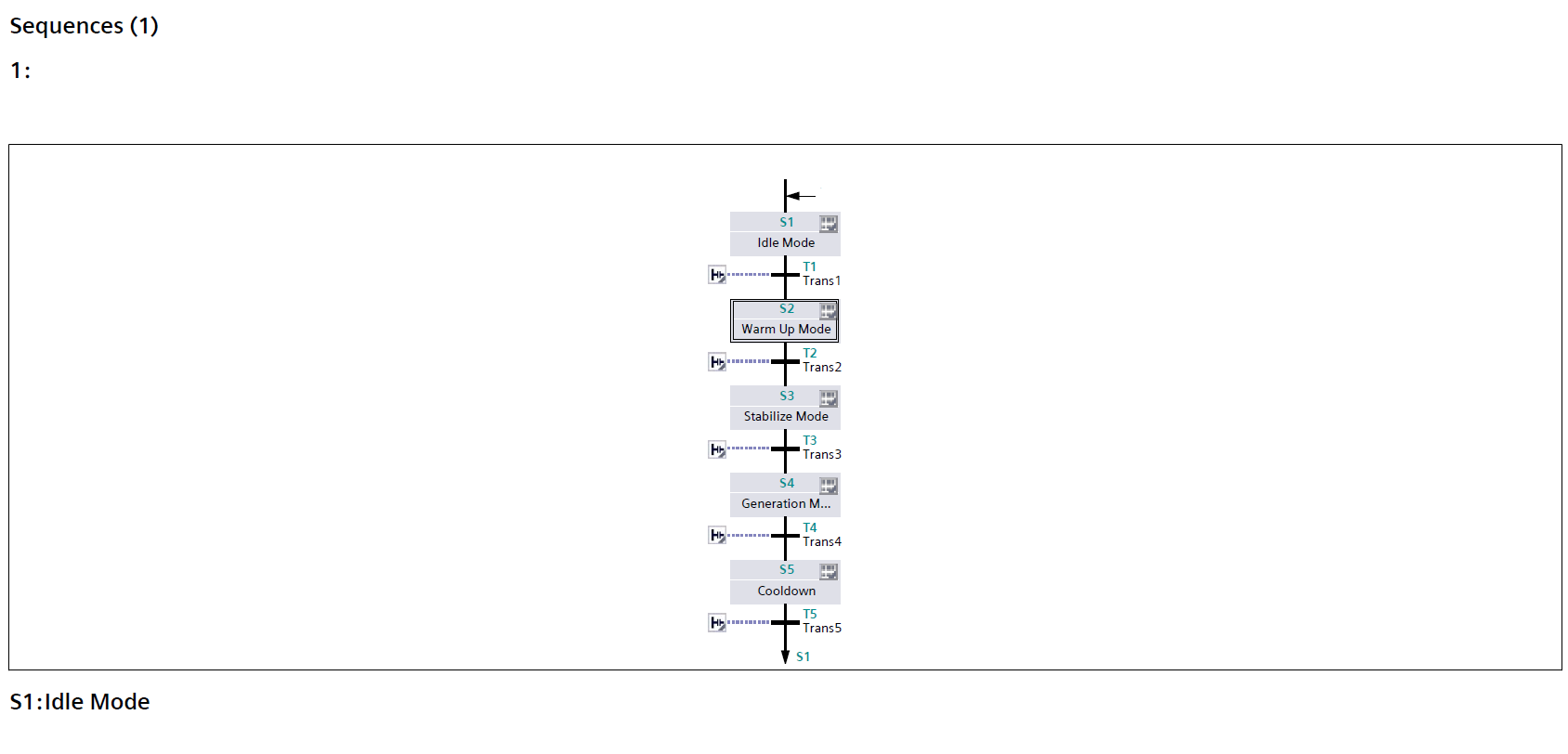

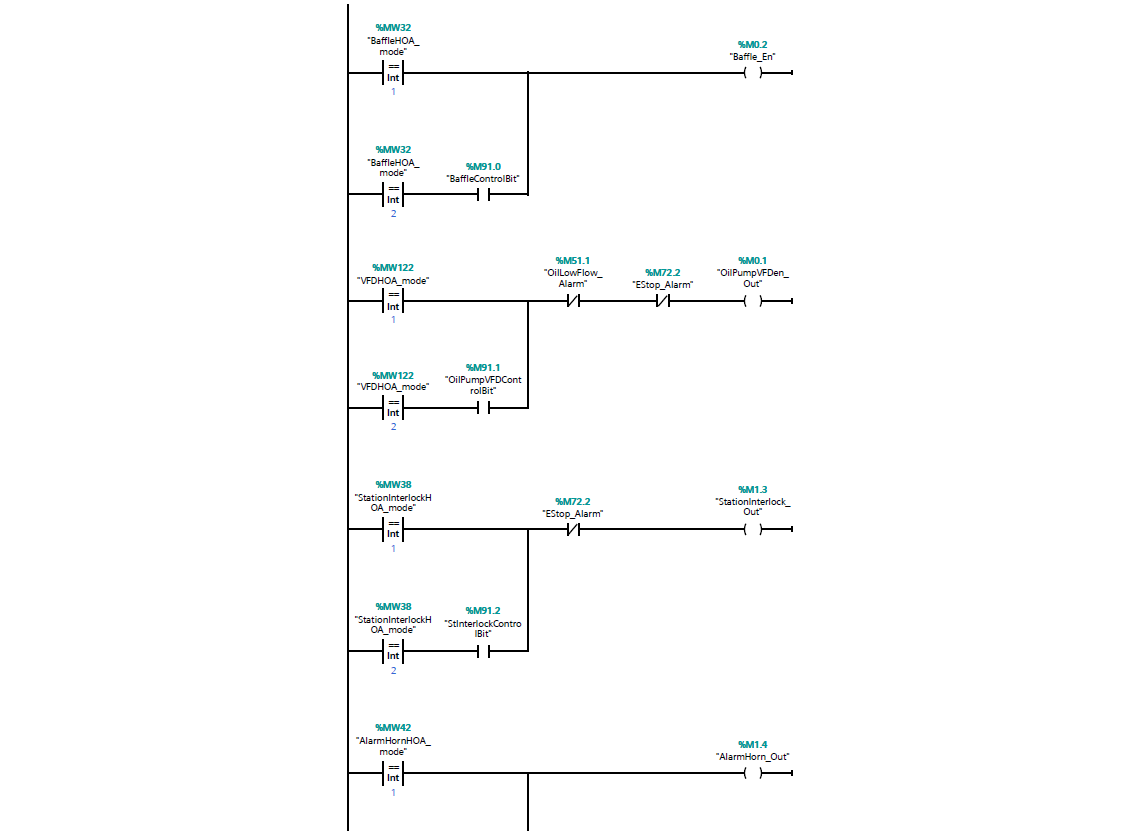

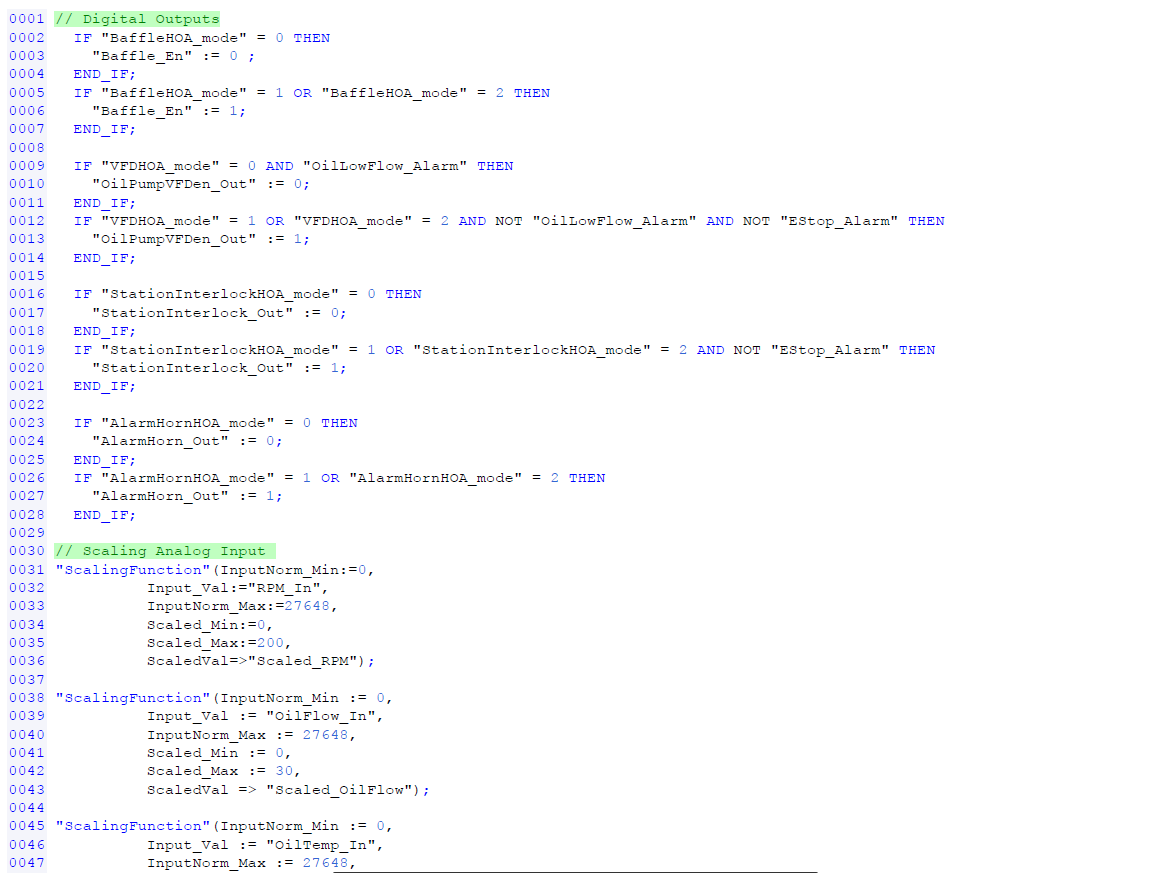

• Used two advanced software, Allen Bradley Rockwell Automation RX Logix 500 programming package & Siemens TIA Portal Step 7 WinCC PLC HMI package to write complex PLC programs to automate industrial processes.

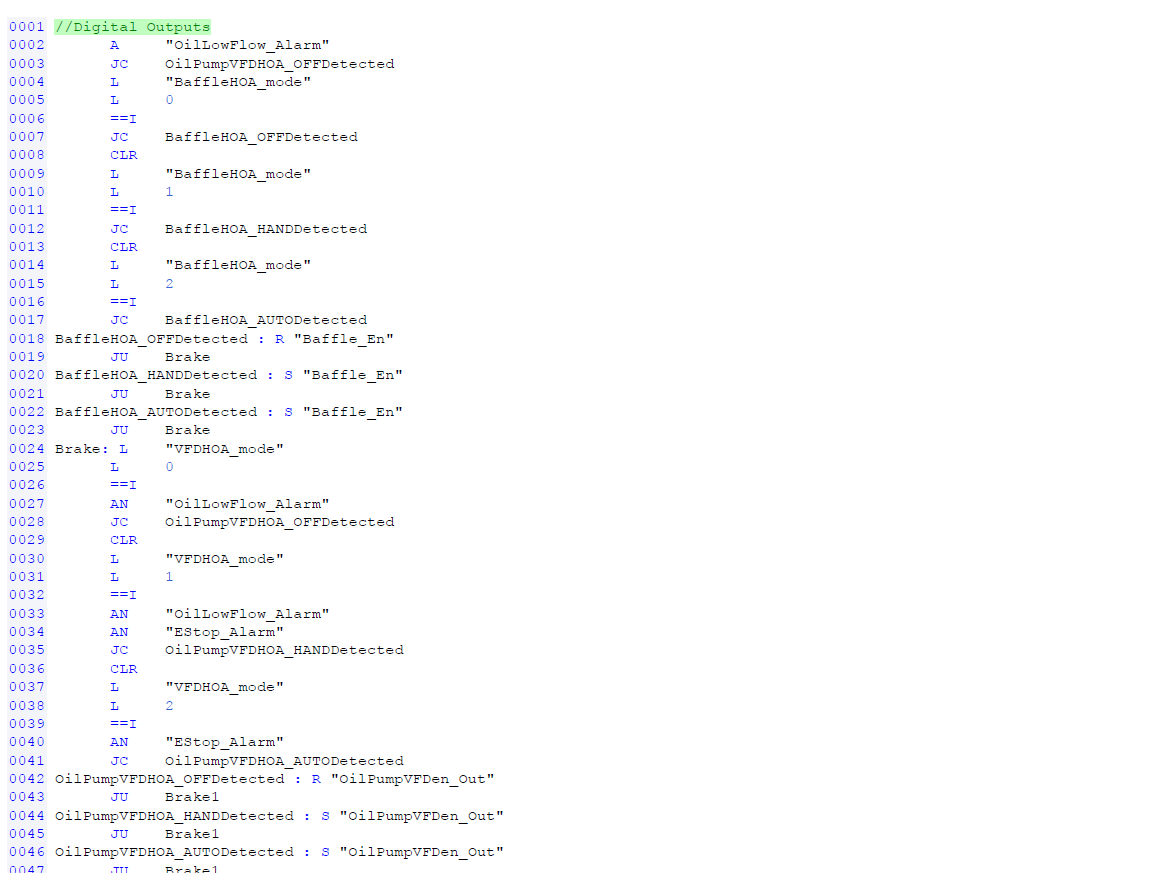

• Implemented 5 IEC languages: Ladder Logic (LAD), Functional Block Diagram (FBD), Structured Controlled Language (SCL), Statement List (STL), Graphical (GRAPH)

• Implemented 5 IEC languages: Ladder Logic (LAD), Functional Block Diagram (FBD), Structured Controlled Language (SCL), Statement List (STL), Graphical (GRAPH)

Software & Skills

Projects list

- Digital Control Logic for maintaining the pressure in a receiver on a compressor application.

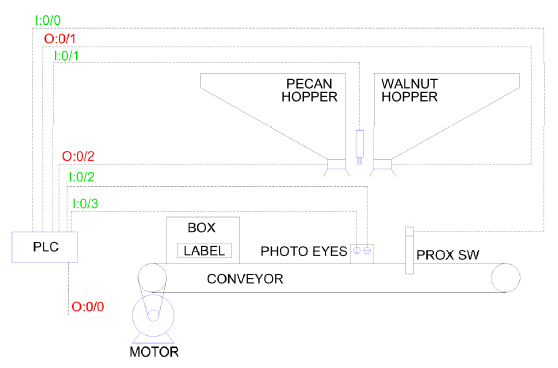

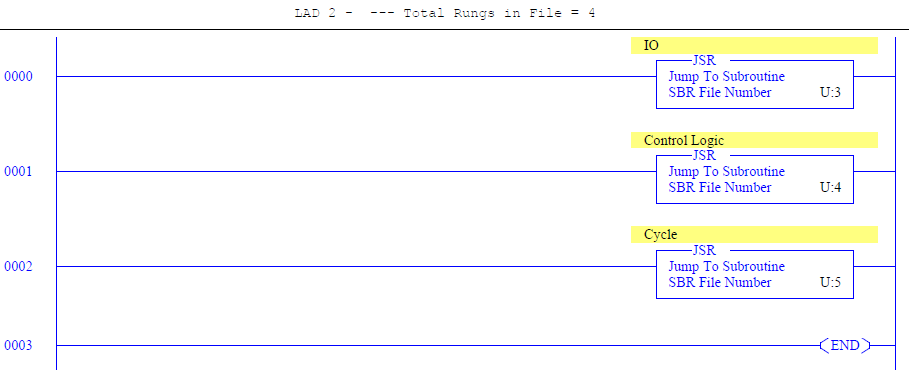

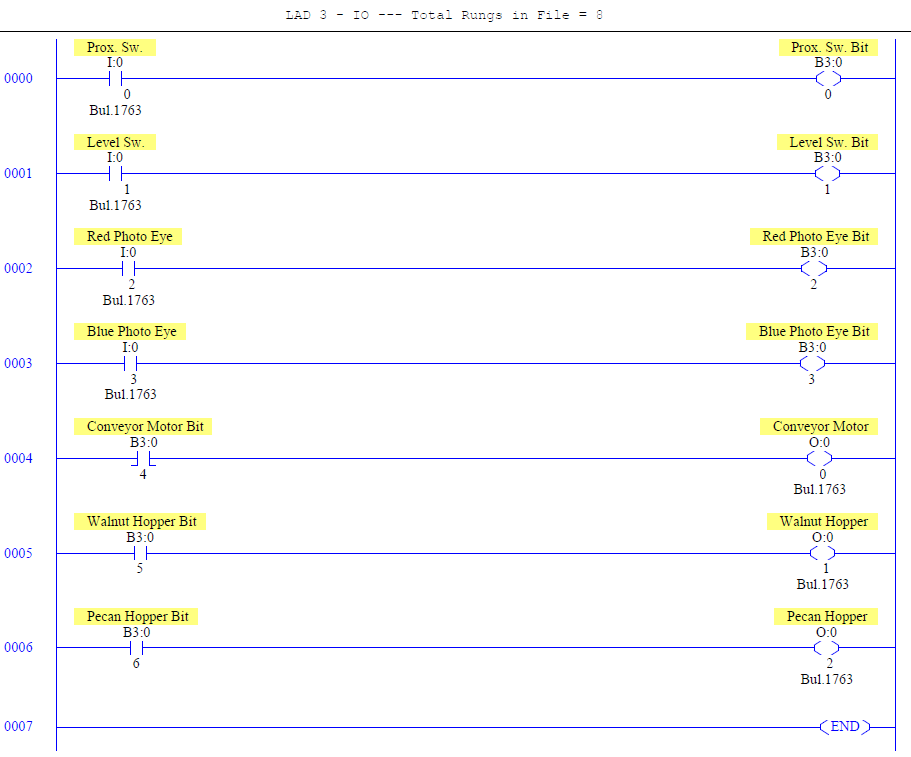

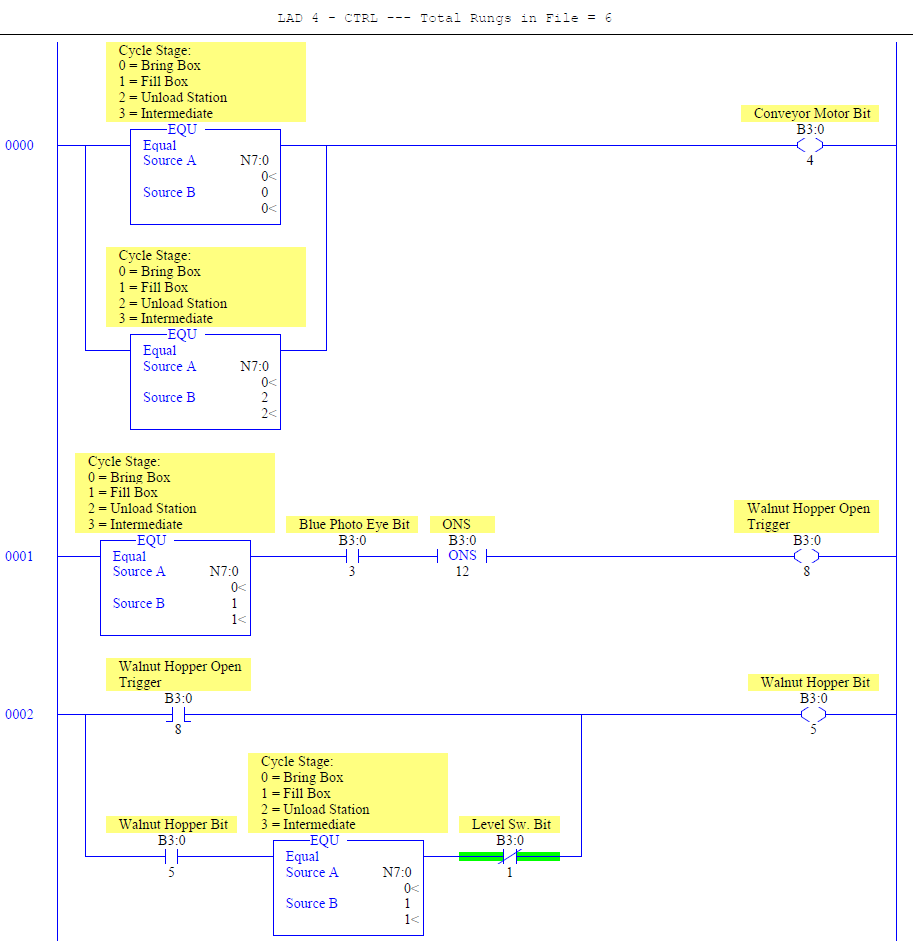

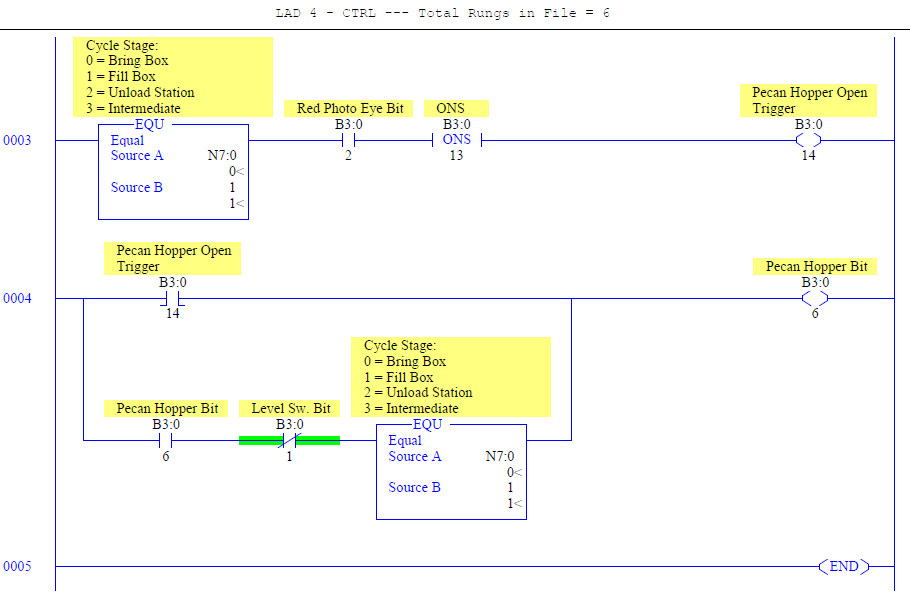

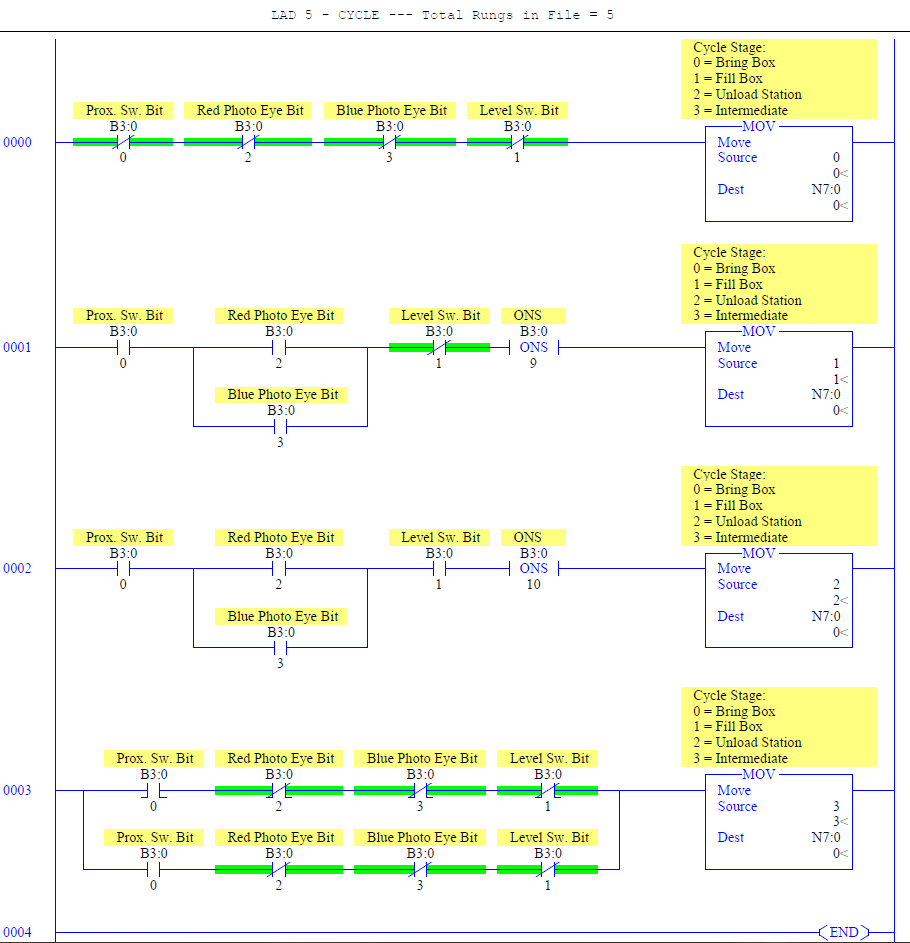

- Digital Filling station for a conveyor belt carrying boxes with colored labels.

- Inventory Management using the barcode scanner for the raw materials.

- Multipurpose Servo Application for a modular water treatment system.

- Digital Rotameter for measuring oil flowing through a pipeline.

- Hour meter to track the runtime of the host plant.

- Sensor Calibration for a system measuring gases.

- PID Substitution Logic for maintaining the vacuum inside a system in spite of a rapidly changing environment.

- DDE Messaging for storing the current mode and function of a system.

- Pump Protection with a flow switch and a pressure sensor using alarms and notifications.

- PLC programming for Hydroelectric Power Plant in Siemens TIA Portal V15 with PLCSIM.