Fault Detection & Prediction of Manufacturing Machines using Machine Learning

Project Summary

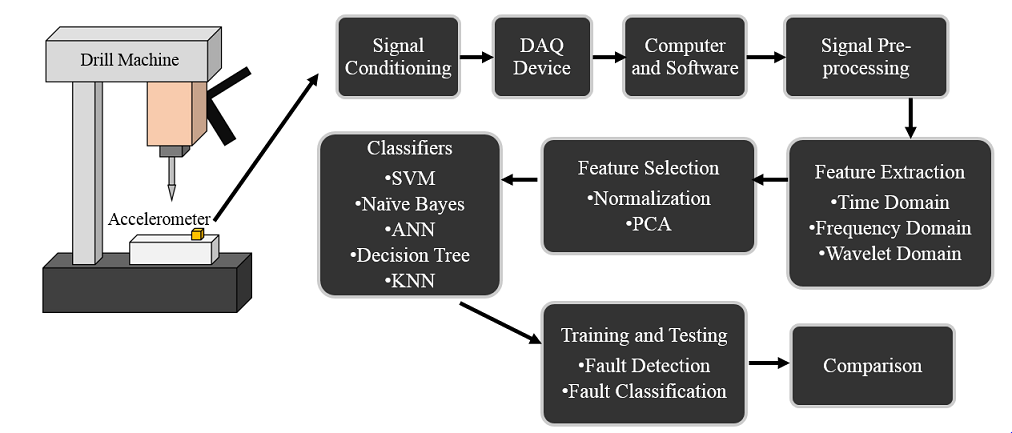

• Developed a predictive maintenance tool for manufacturing machines which can detect faults and its types based on the vibration signal a machine generates which promoted predictive monitoring of tool and manufacturing operations.

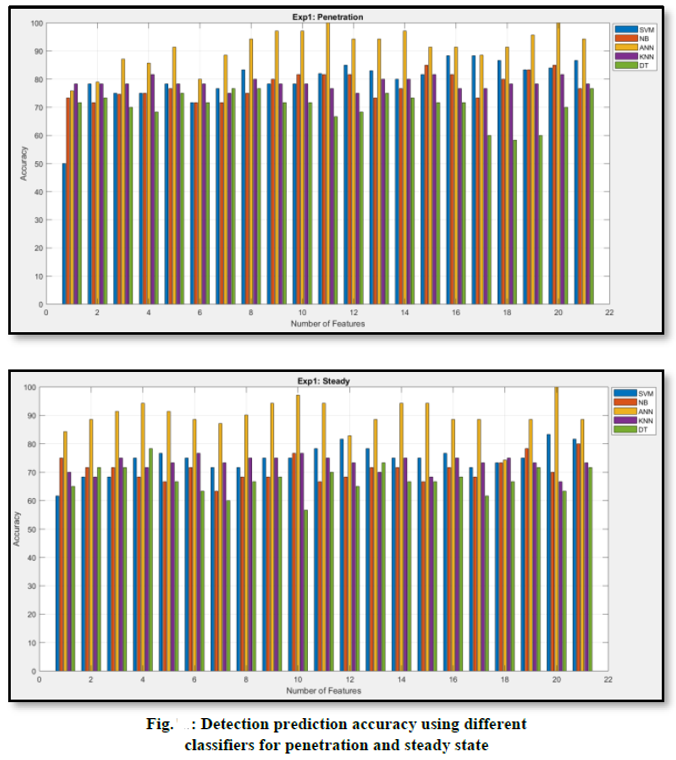

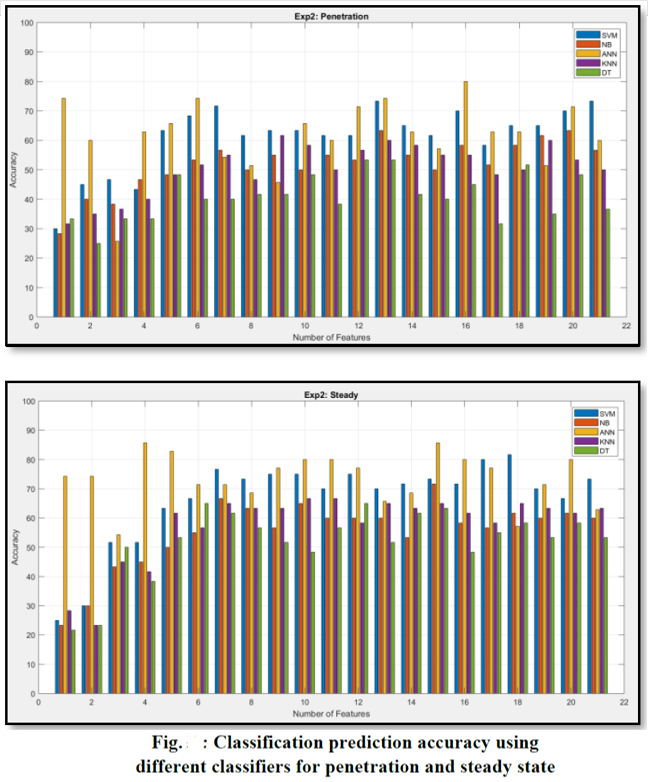

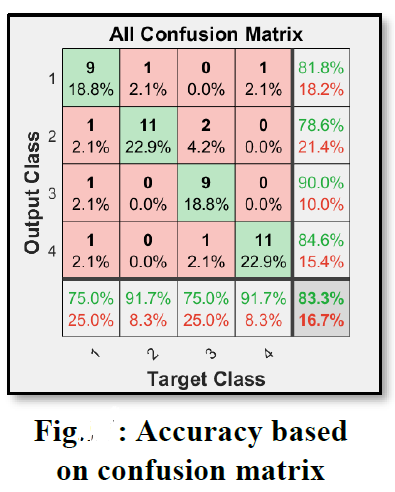

• Used 5 different Machine Learning Classifiers on the actual data set from a drill machine to achieve fault detection & prediction accuracies over 85%.

• Conducted vibration analysis of two different machines using accelerometers, NI DAQ devices LabVIEW & MATLAB. Eliminated system noise by analyzing a large amount of data for preventing tool & equipment failures by implementing DOE & SPC principles.

• Used 5 different Machine Learning Classifiers on the actual data set from a drill machine to achieve fault detection & prediction accuracies over 85%.

• Conducted vibration analysis of two different machines using accelerometers, NI DAQ devices LabVIEW & MATLAB. Eliminated system noise by analyzing a large amount of data for preventing tool & equipment failures by implementing DOE & SPC principles.

Software & Skills

Highlights

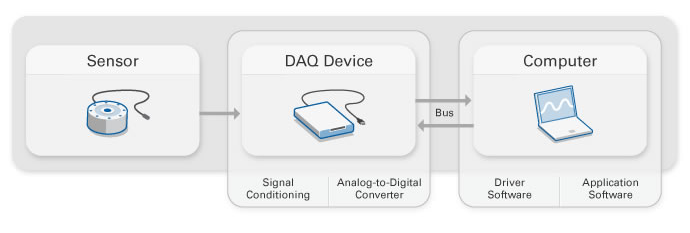

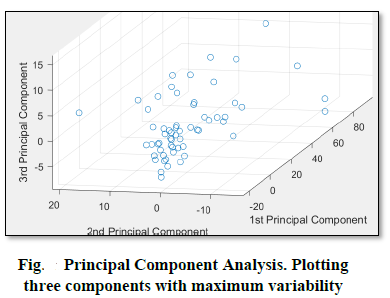

- Equipment included 3-Axis CNC EMCO Concept Mill 105 machine, uniaxial accelerometer, (Model: PCB Piezotronics 603C01; Measurement Range: ± 50 g; Sensitivity: 100 mV/g; Frequency Range: 0.5 to 10000Hz ), National Instrument’s DAQ card Chassis Model: NI cDAQ 9172; Card Model: NI9234; 4-channel; ± 5V; 24-bit software) NI’s LabView 8.0.

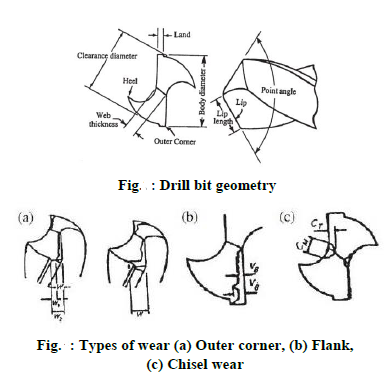

- For this study, HSS twist drill with a body diameter of 9mm was used. Three different kinds of drill bit defects, flank wear, chisel wear and outer corner wear were induced. 15 different drill sets were made combining three feed rates (4mm/min, 8mm/min, 12 mm/min) at five different speeds (160rpm, 170rpm, 180rpm, 190rpm, 200rpm). The fourth kind of drill bit was introduced to make the data set more complicated and to differentiate the data. This drill bit was named as a perfect drill bit, without any faults.

- Data acquisition to measure vibration signals were measured at the sampling rate of 32,768 samples/second for 8 seconds using accelerometer and NI LabVIEW. Later the data was imported in MATLAB workspace for signal pre-processing.

- Five different types of classifiers were used for fault detection analysis like Support Vector Machine, Naïve Bayes, Artificial Neural Network, k-Nearest Neighbour and Decision Tree

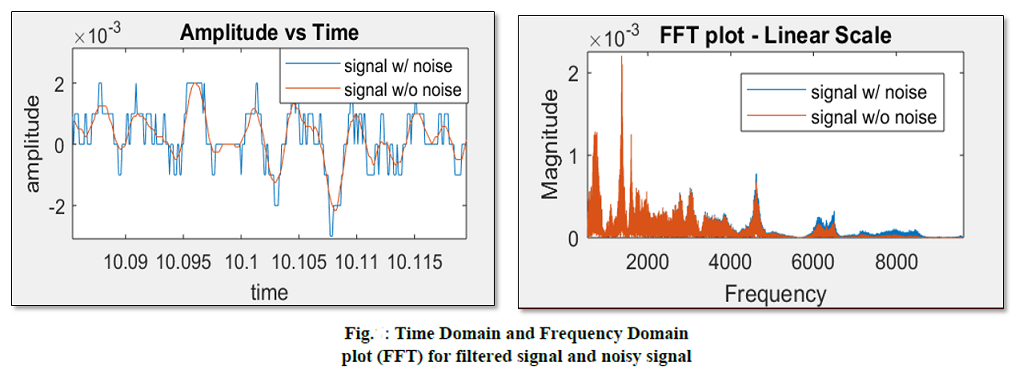

- For signal pre-processing, we used Butterworth lowpass filter with a cut-off frequency of 10000 Hz which attenuates the high-frequency signals above the cut-off frequency.

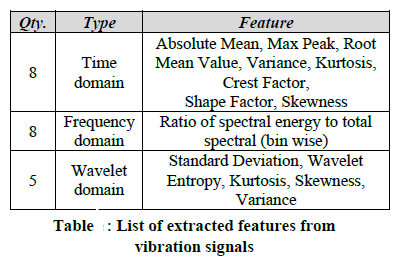

- Features Extraction & Selection, a type of dimensionality reduction that efficiently represents interesting parts of a signal as a compact feature vector, was performed on the raw filtered data to avoid computationally expensive testing.

- Data was normalized before extracting features by applying Principal Component Analysis (PCA). It reduced the data dimensionality to a smaller basis set and converts a set of observations of correlated variables into linearly uncorrelated variables called Principal Components. For one of the data set, the first three components explain 99.18% of all total variability.

- Out of all the classifiers, SVM and ANN classifiers came out on top for the data taken in penetration state in terms of speed and accuracy.