Additive Manufacturing & Design Engineer @ ADDFab Lab

Highlights & Achievements

• Helped a start-up to develop a pilot device for water treatment solution within two months. Used Python code on RPi, Industrial-grade data loggers & sensors to define control cycles and built an interface in PowerBi for data acquisition and analysis.

• Participated as an essential employee in rapid prototyping of supplies like face shields, face masks, respirators parts, N95 mask holders to healthcare workers, first responders and hospitals to fight COVID19. All of it was done by running production 24x7.

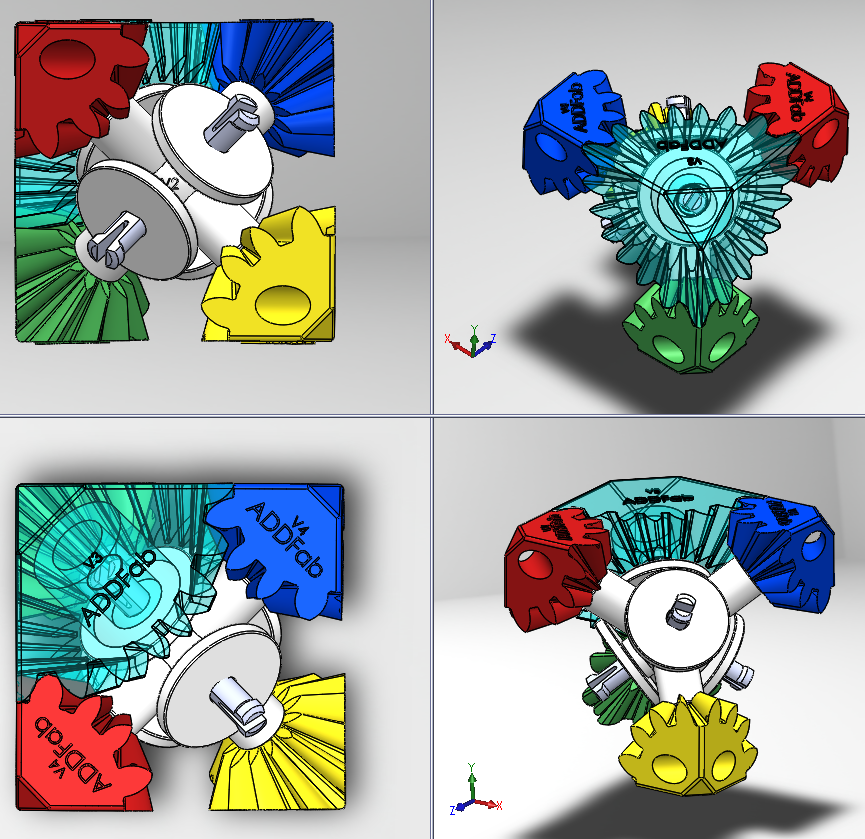

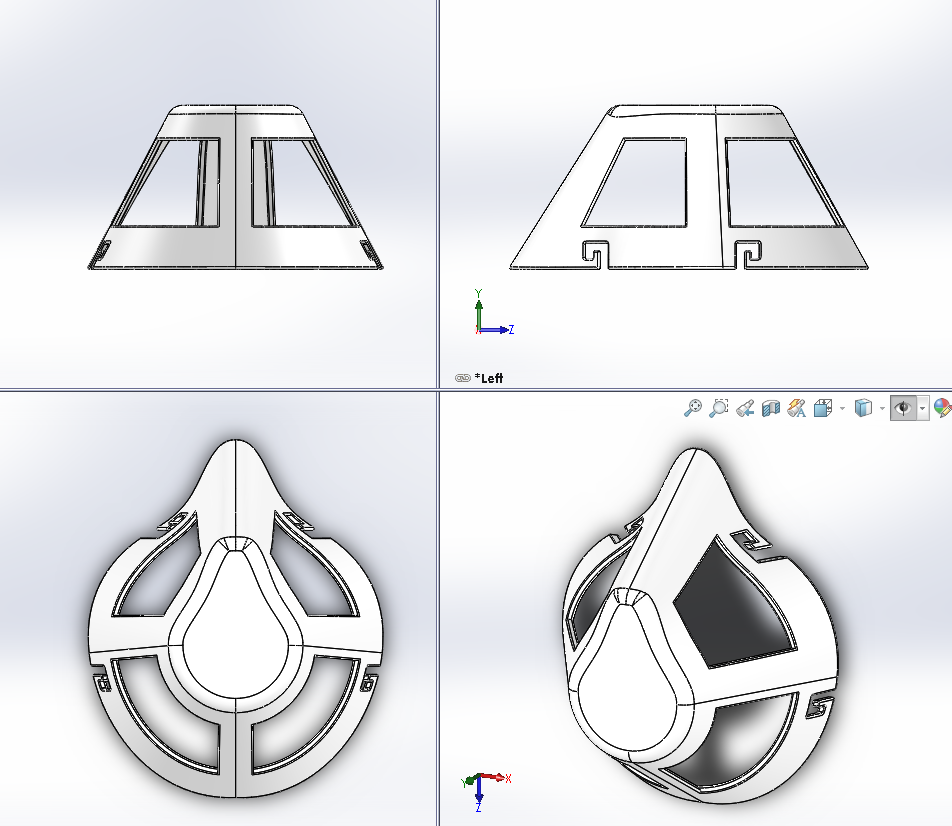

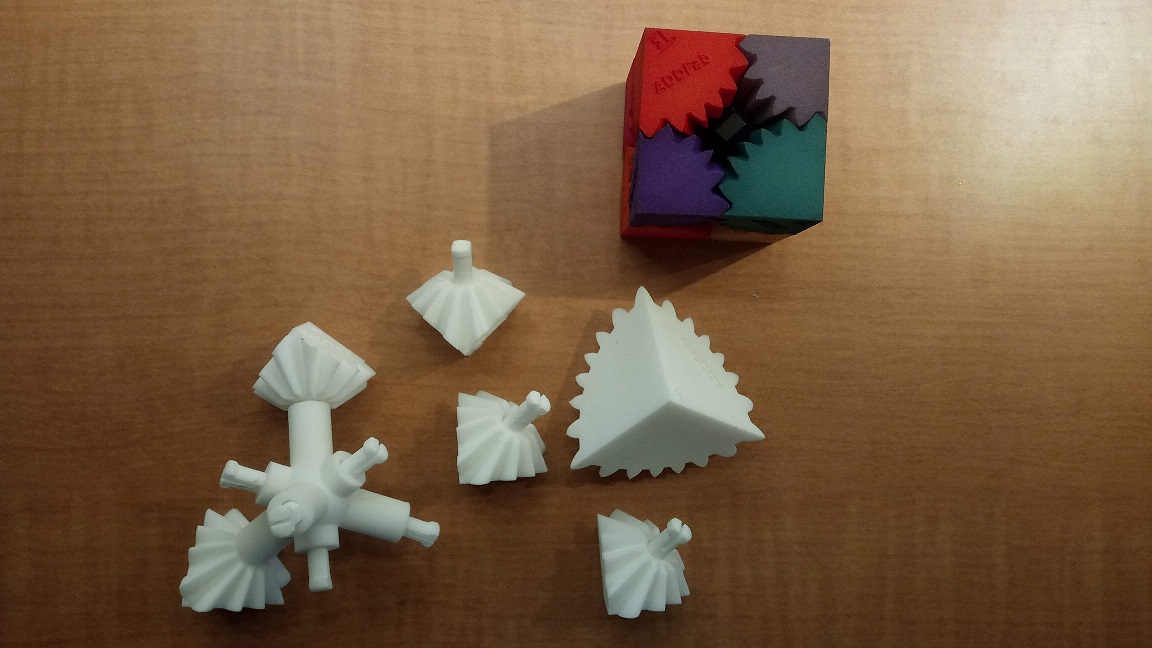

• Designed and developed over 15 parts/ products for clients using SolidWorks and industrial-grade 3D printers (laser sintered nylon & UV cured resin) saving thousands of dollars for initial prototypes and supplied 2D drawings for getting quotations.

• Participated as an essential employee in rapid prototyping of supplies like face shields, face masks, respirators parts, N95 mask holders to healthcare workers, first responders and hospitals to fight COVID19. All of it was done by running production 24x7.

• Designed and developed over 15 parts/ products for clients using SolidWorks and industrial-grade 3D printers (laser sintered nylon & UV cured resin) saving thousands of dollars for initial prototypes and supplied 2D drawings for getting quotations.

Software & Skills

Roles & Responsibilities

- Delivered cost-effective solutions with best-in-class material selection by designing and rapid prototyping complex, functional parts from napkin sketch for R&D initiatives by reducing lead time and eliminating tooling/fixture cost.

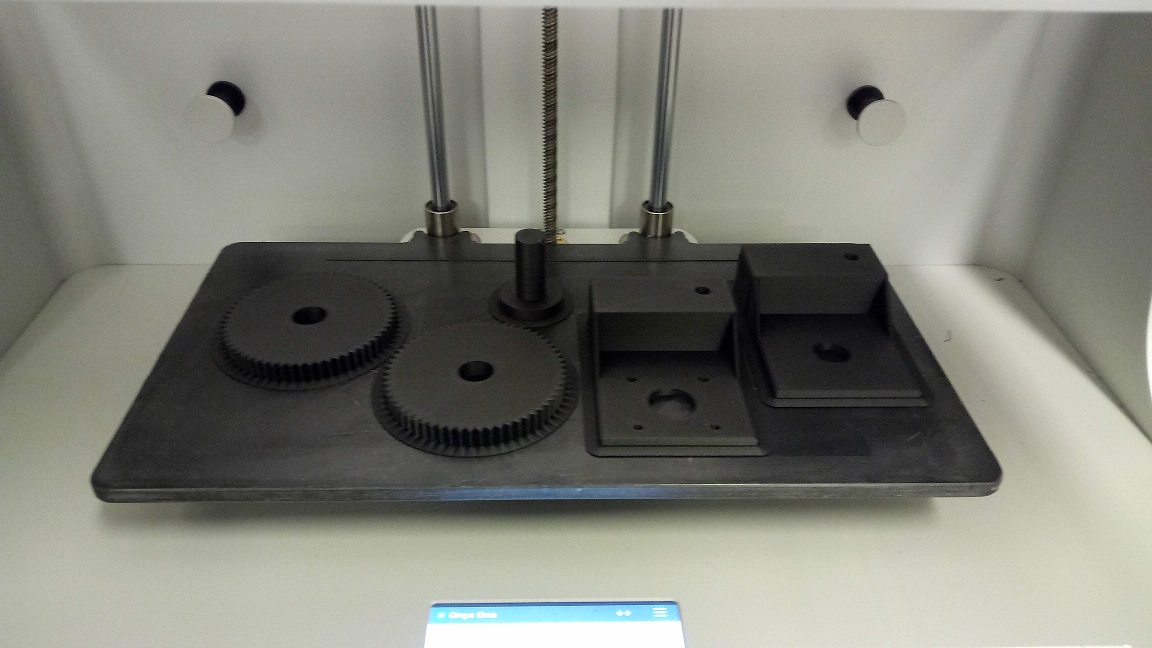

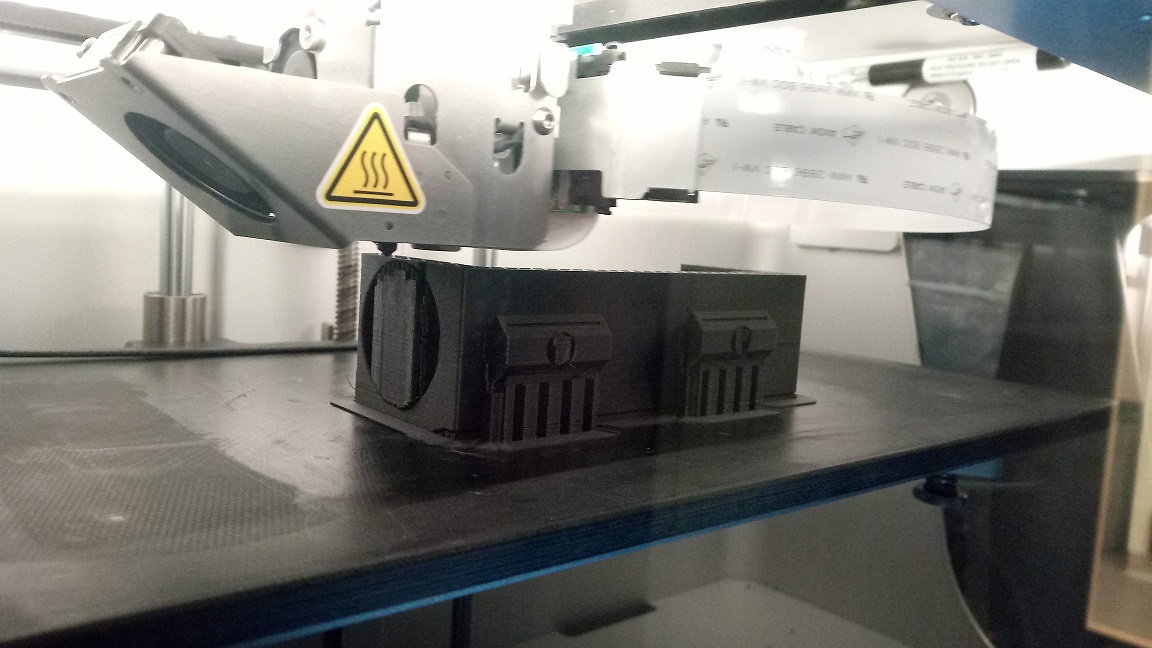

- Independently operated and maintained all 3D printers (EOS, Stratasys, Markforged) and performing routine maintenance activities. Performed all the pre-processing & post-processing to deliver high-quality parts to the customers in less turnaround time.

- Setting up print jobs in AM software like Materialise Magics, Eiger for part orientation, part nesting, supports design, and improved and enhanced part packing density, build job’s success rate and productivity.

- Streamlined traditional manufacturing methods by researching and scrutinizing AM technologies like SLA, DLP, FDM, BJ, SLS, SLM, and LENS for supporting green manufacturing initiatives.

- Achieved quality improvement and defect reduction, energy cost, material waste for 3D printed parts by optimizing build layout, varying print parameters, performing post-processing, tolerance analysis using DFA/ DFM principles.

- Promoted Additive Manufacturing at the university level by giving presentations and providing consultation to eliminate traditional manufacturing methods for developing prototypes.

- Conducted several training sessions on 3D printers and laser cutters to students, researchers and faculties to empower them to use top-notch facilities for their research work

- Explored ways to examine part performance, mechanical properties, and dimensions of printed parts by CMM, Hardness Tester, Instron ElectroPuls.